Introduction

Electrical wire connectors are essential components in any electrical project, providing the necessary means to join wires securely and safely. At One & Only Electrical Service in Los Angeles, we understand the importance of using the right connectors to ensure the safety and efficiency of your home wiring. This comprehensive guide will cover everything you need to know about electrical wire connectors, their types, applications, and tips for proper installation. Whether you’re a DIY enthusiast or looking to hire professionals, this guide will help you make informed decisions.

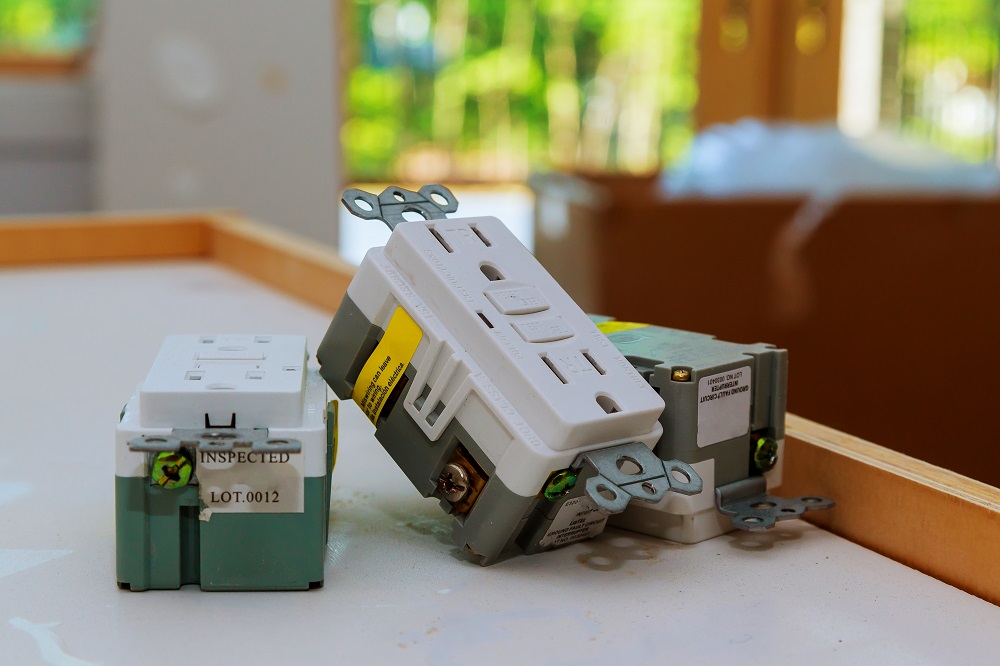

What Are Electrical Wire Connectors?

Electrical wire connectors are devices used to join two or more electrical wires together. They play a crucial role in creating reliable connections that allow electricity to flow smoothly. The right connector can enhance the performance of your electrical system while reducing the risk of accidents and failures.

Why Are They Important?

- Safety: Proper connectors minimize the risk of electrical fires and shocks by ensuring strong and stable connections.

- Efficiency: Quality connectors help maintain consistent electrical flow, which is vital for the optimal functioning of appliances and devices.

- Longevity: Using the right connectors can extend the lifespan of your wiring and electrical components, preventing costly repairs or replacements.

Types of Electrical Wire Connectors

Understanding the different types of electrical wire connectors is essential for choosing the right one for your project. Below are some of the most common types used in residential wiring.

1. Twist-On Wire Connectors

Twist-on wire connectors, often referred to as wire nuts, are the most commonly used connectors in residential electrical work. They are designed to secure multiple wires together by twisting them into the connector.

Advantages:

- Easy to Use: Requires minimal tools and can be installed quickly.

- Versatile: Works with various wire sizes and types.

- Affordable: Cost-effective and widely available.

Applications:

- Ideal for connecting wires in junction boxes and lighting fixtures.

2. Crimp Connectors

Crimp connectors are metal connectors that secure wires by crimping them together, often using a specialized tool. They provide a robust and reliable connection.

Advantages:

- Strong Connection: Offers high reliability, especially in high-vibration environments.

- Quick Installation: Easy to install with the right crimping tool.

Applications:

- Commonly used in automotive and industrial applications.

3. Solder Connectors

Solder connectors involve melting solder to join wires together, providing a solid connection. This method is often used in more permanent installations.

Advantages:

- Durability: Offers a long-lasting connection.

- Excellent Conductivity: Minimizes resistance and enhances electrical efficiency.

Applications:

- Suitable for specialized electrical systems and high-performance applications.

4. Insulated Terminal Connectors

These connectors come with plastic insulation to protect against accidental contact with live wires, enhancing safety.

Advantages:

- Safety: Reduces the risk of short circuits and electric shocks.

- Color-Coded Options: Makes it easy to identify the appropriate connector for different wire sizes.

Applications:

- Commonly used in circuit breaker panels and electrical outlets.

5. Push-In Wire Connectors

Push-in wire connectors allow for quick and simple connections without the need for additional tools. You simply push the stripped wire into the connector.

Advantages:

- User-Friendly: Perfect for quick installations, especially for beginners.

- Compact Design: Ideal for tight spaces.

Applications:

- Suitable for various home wiring projects, including light fixtures and outlets.

Choosing the Right Electrical Wire Connectors

When selecting electrical wire connectors, consider the following factors:

1. Wire Gauge

The connector must match the wire gauge to ensure a secure connection. Always check the specifications provided by the manufacturer.

2. Application

Different connectors are designed for specific applications. Choose a connector based on the project’s requirements and the environment in which it will be used.

3. Capacity

Each connector has a maximum current capacity. Ensure the connector can handle the electrical load of your system to prevent overheating.

4. Type of Connection

Determine whether you need a temporary or permanent connection. Twist-on and crimp connectors are typically more permanent, while push-in connectors can be more temporary.

Best Practices for Installation

To ensure a safe and effective electrical setup, follow these best practices when using electrical wire connectors:

1. Strip Wires Properly

Use a wire stripper to remove the insulation from the wire, ensuring the correct length is stripped for a secure connection.

2. Twist Wires Together (if applicable)

For twist-on connectors, make sure to twist the wires together firmly before adding the connector.

3. Secure Connections

Always ensure that the connector is secured tightly to prevent accidental disconnection.

4. Use Insulated Connectors When Necessary

For outdoor or high-risk installations, use insulated connectors to protect against moisture and accidental contact.

5. Inspect Regularly

Conduct regular inspections of your electrical connections to check for signs of wear, corrosion, or damage. Replace any damaged connectors immediately.

Frequently Asked Questions (FAQ)

Q1: What types of wire connectors are best for home wiring projects?

A1: Twist-on wire connectors and insulated terminal connectors are typically the best choices for home wiring projects due to their versatility and safety features.

Q2: How do I know which connector to use for my project?

A2: Consider the wire gauge, application, and current capacity of the connector. Consult manufacturer specifications for guidance.

Q3: Can I use the same connector for different wire gauges?

A3: No, using a connector that doesn’t match the wire gauge can lead to poor connections and potential hazards. Always choose connectors designed for the specific gauge of wire.

Q4: How often should I inspect my electrical connections?

A4: It’s advisable to inspect electrical connections at least once a year or more frequently if you notice any signs of wear or damage.

Q5: What should I do if I encounter damaged connectors?

A5: If you find damaged connectors, replace them immediately to maintain safety. If you’re unsure how to proceed, consult a licensed electrician.